Technology

We leave our product in the hands of real professionals.

Each GRAND is made by hand, one at a time. Behind every model is tough, durable and hand-crafted manufacturing process that stands up to the toughest environment mother nature throws on our way. Outmost skilled manufacturing specialists and a top-notch, quality control system are combined to provide the best guarantees and highest level of quality. We leave our product in the hands of real professionals. We would have it no other way!

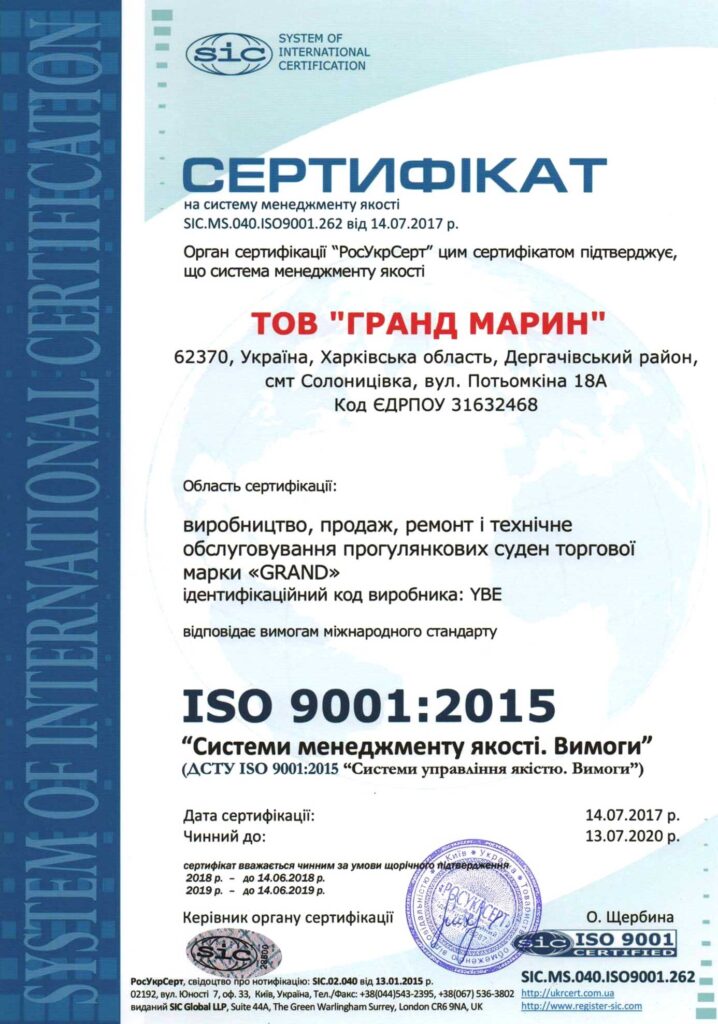

As part of our focus on continually improving our products and services we are delighted to announce that we have recently achieved ISO 9001:2015 status. ISO 9001 is the international standard for quality management systems and is recognized in over 170 countries. The standard is based on a number of quality management principles including a strong customer focus, the motivation and engagement of top management, the process approach, and continual improvement. Using ISO 9001 helps us ensure that customers consistently receive quality products and services, which in turn brings many shared business benefits.

ISO 9001:2015 in Ukrainian

ISO 9001:2015 in English

We use HYPALON tubes ORCA® engineered fabric which provides the quality, strength and durability necessary to ensure customers receive the best performing products available. These fabrics combined with our new HTL adhesive ensures our products possess a high level of structural integrity and the ability to withstand temperatures of up to 90°C! Every GRAND boat utilizes special marine Gelcoats - Crystic® from Scott Bader or Maxguard® from Ashland with lowest styrene contents available today.

Productive

About 2,000 boats are produced per year

Efficient

More than 30,000 boats have been produced since 2001

Experience

More then 70 models of boats have been released since 2001

Modern

10 new models of boats have been represented since 2014

Production

15,000 m² production area

Large Team

300 people are qualified stuff

Dealers

32 country dealer network

Worldwide

300+ service centres worldwide

Our primary consideration is to provide a safe environment for Our Customers. The safety aspects of every new model are therefore thoroughly reviewed at the start of the design process. Regardless of which model you choose; be it our baby E210 or perhaps an S330L tender for your yacht or the fabulous G850 Day Cruiser — you will always feel safe in a GRAND Inflatable Boat.

The ability to continually innovate and refine our production processes is one of the key ingredients in GRAND’s success. By utilizing state of the art engineering and design processes combined with an extensive research and development program we have not only raised the bar in terms of quality but have also been able to provide some of the finest contemporary naval architecture available!

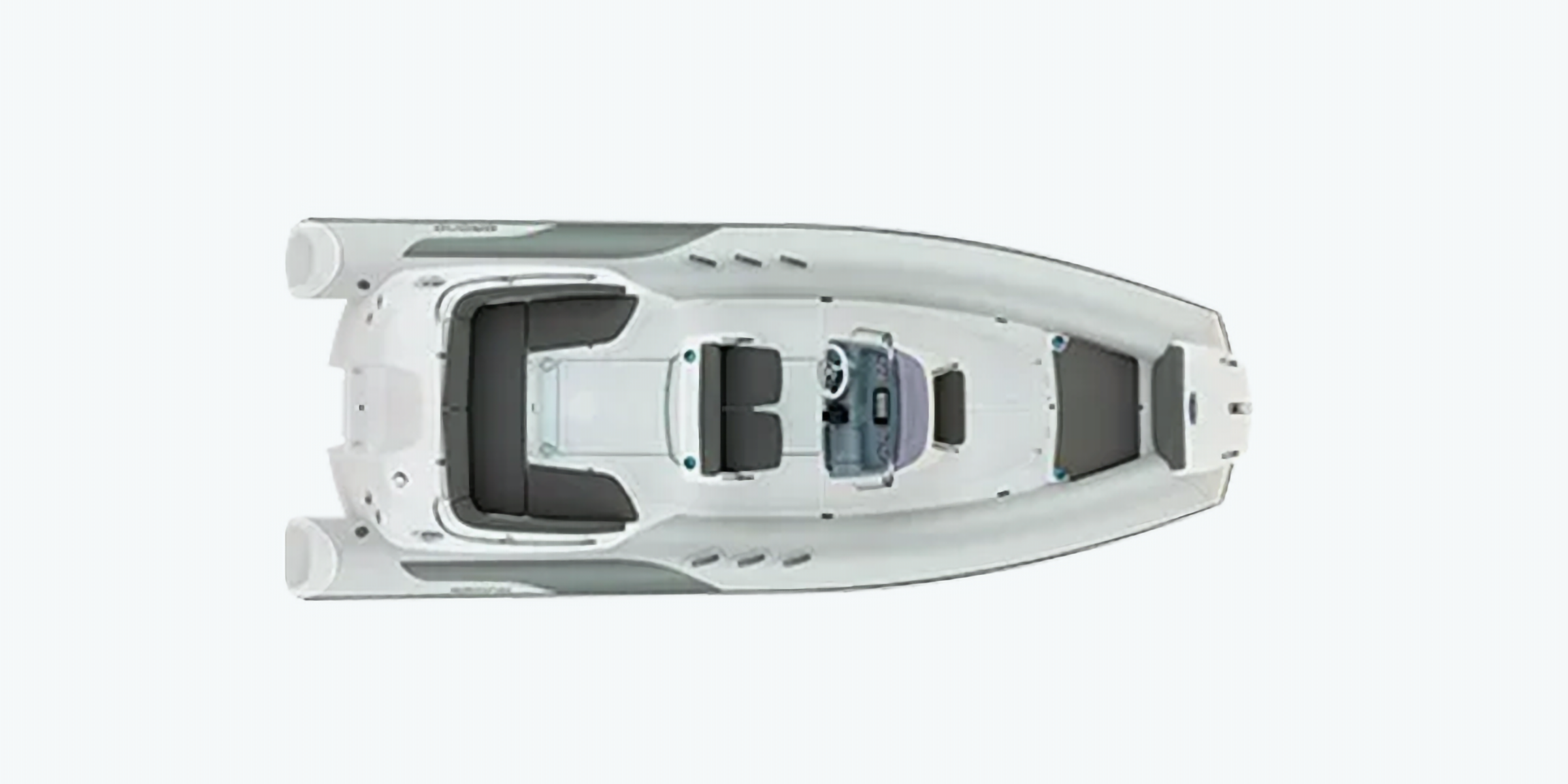

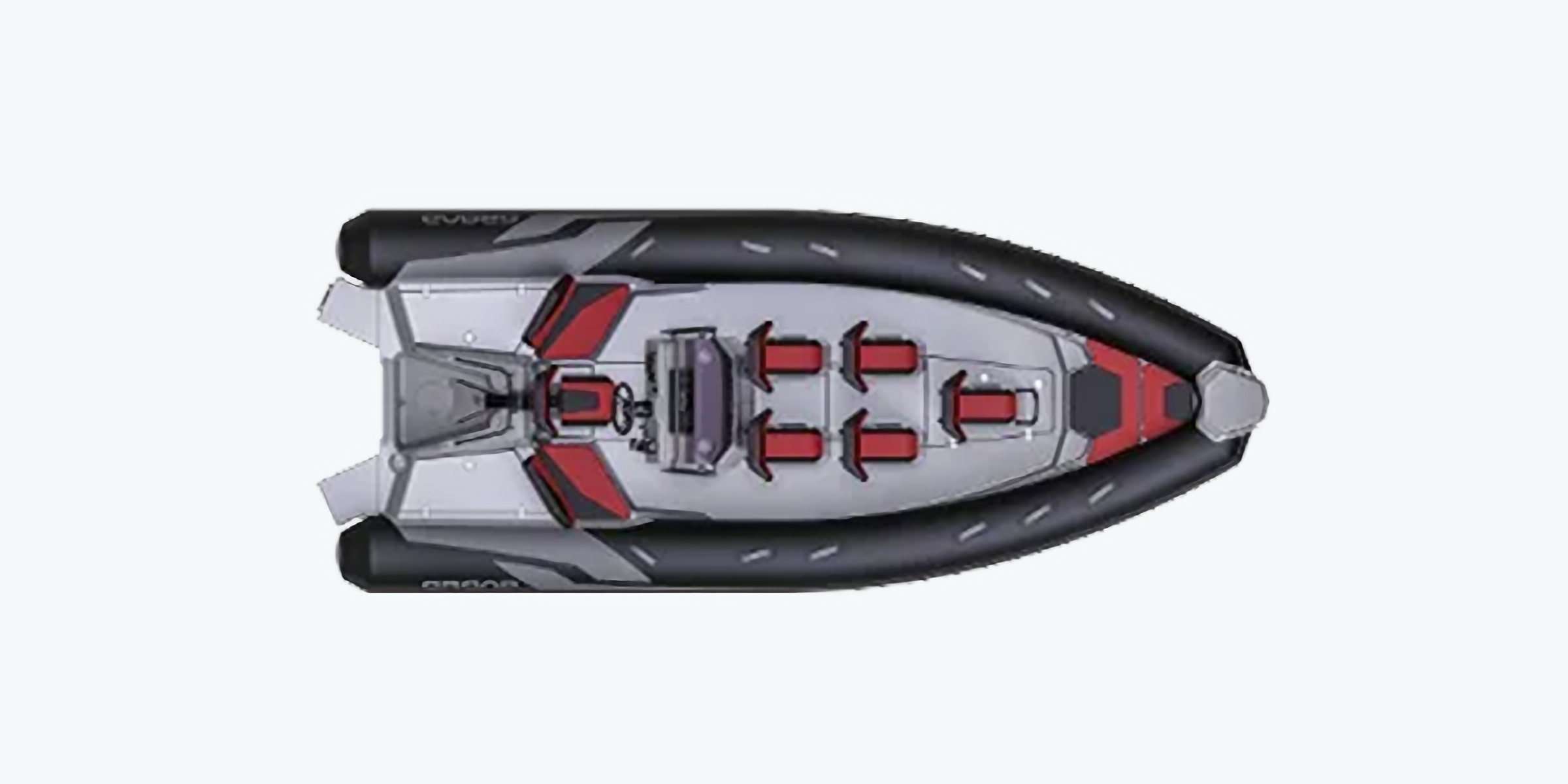

Every GRAND model incorporates a unique combination of innovative techniques, patented designs plus many years of experience and expertise. By utilizing the latest CAD/CAM technology with the most advanced software, every GRAND is perfected to the smallest detail to ensure the utmost quality. Once the prototype model has been constructed, it is subjected to an extensive range of sea trials in the toughest conditions before it sees a showroom floor! After every production stage each boat passes a strict quality control test against a challenging set of parameters and all models are required to pass CE certification before series production begins.

All of our RIBs (except G850 & G750) include, as standard equipment or as an option, a feature developed by GRAND – inflatable tubes with Profiled Fiberglass Step Ends. The advantages include: They are a particularly useful feature when swimming, boarding or docking They are safe and comfortable to stand or sit on when the boat is at rest. They work as a passive trim-tab, pushing the bow down when under way. Once you have enjoyed the advantages of our Step Ends you won’t want to be without them!

GRAND GOLDEN LINE boats are now available with SeaDek high performance flooring. SeaDek® is manufactured from a nonabsorbent, closed cell copolymer material specially formulated for marine applications. This material is an innovative, textured micro-dot surface with enhanced non-slip characteristics. SeaDek is a durable UV resistant non-absorbable material providing protection for boat surfaces, especially in high traffic areas.